PHILIP : Powering

Rovers by High Intensity Laser Induction on Planets

by using High Intensity Laser Power Beaming System

Funding organization: European Space Agency (ESA)

Coordinator: Leonardo S.p.A,

Italy

Partner:

INOE 2000, Romania

Project manager for partner: Dr. Mariana Braic

Team:

Dr. Viorel Braic - Key person,

Dr. Iulian Pana.

ABSTRACT

The scenarios that have been identified anticipate operations on

the south polar surface of the Moon, including areas where solar energy collection

presents challenges, such as Permanently Shaded Regions (PSR).

Investigating PSR is the goal. Traditional powering systems

require the rover to periodically exit the PSR for batteries replenishment.

Using radioactive materials as a power source is an alternative strategy. One

example of this is the plutonium Multi Mission Radioisotope Thermoelectric

Generator installed on the NASA/JPL MSL mission's Curiosity Rover.

In addition to the aforementioned, large batteries would be

required for the rover to travel deep within the PSR, which would make

designing the vehicle extremely challenging in terms of mass and volume.

In PHILIP project a novel strategy is investigated: using a high power laser beam that is directed out of the lander and

into the rover's line of sight, the rover can be powered continuously, allowing

it to enter the PSR without interruption and without the need for radioactive

materials.

Designing an optical system with the goal of expanding the laser

beam out of the fiber connector to a defined diameter and orienting it toward

the rover using steering mechanisms is the task assigned to INOE 2000.

The laser beam diameter must be designed to ensure the minimum

divergence, allowing the photovoltaic panel to collect the same amount of power

density on the photovoltaic cells along the rover range excursion, in order to

illuminate the rover within 4 km of the target distance or 15 km.

RESULTS

Initial plan: After the first beam expander (Bex), the movement of

the plane mirror revealed a significant shift in the beam position at large

distances, which was deemed unacceptable when taking into account a 40 mm laser

beam (wavelength 1070 nm) diameter. In this model, a PV panel with a lateral

dimension of 0.54 meters was taken into account. Additionally, since the BEx#2 and the steering mirror

should only have one moving platform, the mass of the selected mirror was

deemed prohibitive.

Our calculations indicated that for a maximum laser beam

deflection of 0.0040, the beam will stay on the panel, taking into account the

potential angular movement of the mirror and the requirement for the image to

remain on the PV panel. This angular value, however, was deemed unacceptable

since it would place severe restrictions on the steering mechanism's ability to

move accurately.

A second design with a mix of parabolic mirrors was released. The

parabolic mirrors M1 and M2 were the ideal arrangement. The selected reflected

focal length (F1) for M1 was also calculated issuing a feasible value from the

point of view of manufacturing constraints.

The M1 mirror's diameter was selected due to its excellent fit

with the incident collimated beam diameter. Additionally, a small F1 value

makes it possible to obtain a compact setup system in terms of mass and size by

allowing for a short distance to the second mirror. To enable the optical setup

to have a compact structure, an extra plane mirror was added. We made use of

mirrors, which reputable manufacturers can provide.

Several image diameters (ID) at 5, 10, and 15 km, were calculated

using the design with two parabolic mirrors. Several input beam diameters

supplied by a collimated laser source were taken into consideration. The

variation of the PV panel's image diameter (ID) at 4 and 15 km, as well as the

necessary magnification, were calculated to determine the optimal value of F2.

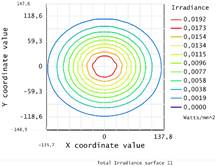

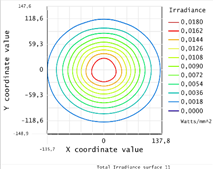

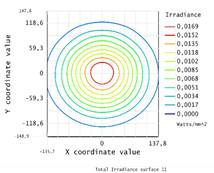

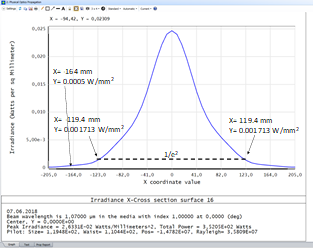

The calculated image diameter (ID) at 4, 10, and 15 km, as well as

the irradiance, are modeled in the figure below, taking into account the two

parabolic mirrors with optimized focal points (Fi) and a certain collimated

laser beam diameter. The Gaussian beam profile at 15 km distance from the laser

is also shown.

|

4 km |

10 km |

15 km |

|

|

|

|

|

|

|

ID = X mm |

ID = X+7 mm |

ID = X+17 mm |

|

The optical setup was viewed as a single module to maintain the

components' constant positions. The laser beam collimator, which is attached to

the laser exit via an optic fiber (FO), is housed on the base plate of the

optical system. A plane mirror deviates the beam that emerges from the

collimator at a 90-degree angle. In order to connect to their holders, the two

parabolic mirrors should be fitted with appropriate tapered holes and machined

to the lowest mass permitted.

Conceptual optical arrangement taking the needs for steering into

account: There were two distinct steering requirements: coarse mode and fine

mode. In the coarse mode, a gimbal holder rotates the optics base in two

planes. After accounting for the scanning process that keeps the laser beam in

contact with the PV panel, we have determined that few tens of nm resolution of

a piezo actuator causes a shift in position of less

than 10-7 radians. Given that a position change of about 10-5

rad is required to move the laser beam along half of the PV panel, resulting

that the piezo-actuator's resolution is found to be adequate. Additionally, the

piezo actuators could be commercially available vacuum-compatible piezo-motors.

To track the rover's movement in the fine mode without losing

contact with the PV panel, the beam needs to have an appropriate moving

resolution. A solution with the base plate positioned on a platform resembling

the base plate emerged, taking into account the rover's speed and distances as

well as the requirement for beam steering in two planes. Although the solution

is comparable to the currently available tilt and rotate optical holders sold

in stores, it needs to be modified to account for the optical setup's weight

and dimensions. A setup for precise positioning was also defined.